If you’ve misplaced your booklet or purchased a used unit, finding a reliable Master Mechanic 1 2 Hp Garage Door Opener Manual can be frustrating. Without proper instructions, installation errors or incorrect programming can lead to safety issues and performance problems.

This complete guide recreates the essential manual information you need—covering installation, wiring, programming, troubleshooting, and maintenance for your 1/2 HP Master Mechanic opener.

Read too: The Complete Guide to Tighten Chain On Garage Door Opener for Smooth Operation

Master Mechanic 1 2 HP Garage Door Opener Manual Overview

The Master Mechanic 1 2 Hp Garage Door Opener Manual typically includes:

- Installation instructions

- Safety warnings

- Wiring diagrams

- Travel limit settings

- Remote programming steps

- Maintenance recommendations

Master Mechanic garage door openers were commonly sold through hardware retailers and share design similarities with other chain-drive residential systems.

Garage door openers are electromechanical systems, combining electric motors and control circuits, as described generally under Wikipedia.

Safety Instructions (Read Before Installation)

Before beginning installation or service:

- Disconnect power before wiring

- Do not adjust torsion springs (dangerous under tension)

- Install safety sensors 5–6 inches above floor

- Test auto-reverse function after setup

Failure to follow safety steps can result in injury or property damage.

Installation Guide (Step-by-Step)

Tools Required

- Power drill

- Socket wrench

- Level

- Ladder

- Tape measure

- Screwdrivers

Estimated installation time: 3–5 hours

Step 1: Assemble Rail and Chain

- Lay rail sections on floor.

- Connect segments securely.

- Install chain around sprocket.

- Adjust chain tension—allow about 1/2 inch slack.

Proper tension prevents excessive motor strain.

Step 2: Mount Header Bracket

- Install bracket above garage door center.

- Secure to structural framing, not drywall.

Height should allow proper rail angle alignment.

Step 3: Attach Rail to Header

- Connect rail to bracket using clevis pin.

- Ensure secure locking clip placement.

Step 4: Mount Motor Unit to Ceiling

- Use angle iron brackets.

- Secure to ceiling joists.

- Ensure motor unit remains level.

Step 5: Install Door Arm

- Attach door bracket to top panel center.

- Connect curved and straight arms.

- Secure with bolts.

Step 6: Install Safety Sensors

Mount sensors:

- 5–6 inches above floor

- Directly across from each other

LED indicators should remain steady when aligned.

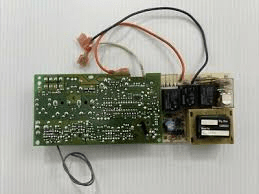

Wiring Diagram Instructions

The Master Mechanic 1/2 HP opener uses low-voltage wiring for:

- Wall control

- Safety sensors

Typical Terminal Layout

- White → Common

- White/Black → Wall control

- Sensor wires → Separate terminals

Never run low-voltage wires through the same conduit as high-voltage wiring.

Programming Travel Limits

Setting limits ensures door stops properly.

To Set Open Limit:

- Press “Up” adjustment button.

- Raise door to desired height.

- Press “Set” to confirm.

To Set Close Limit:

- Press “Down” adjustment button.

- Lower door to floor contact.

- Confirm with “Set” button.

Test full cycle 2–3 times.

Remote Programming Instructions

Most Master Mechanic units use a “Learn” button.

To Program Remote:

- Press and release “Learn” button.

- Within 30 seconds, press remote button.

- Wait for light flash confirmation.

Repeat for additional remotes.

Common Troubleshooting Guide

Door Does Not Respond

Check:

- Power outlet

- Circuit breaker

- Wall control wiring

Door Reverses Immediately

Likely causes:

- Safety sensor misalignment

- Travel limit improperly set

- Obstruction on floor

Remote Not Working

- Replace battery

- Reprogram remote

- Check antenna wire position

Motor Runs But Door Does Not Move

Possible issue:

- Broken chain

- Stripped drive gear

- Disconnected trolley

Maintenance Schedule

Regular maintenance extends lifespan.

Monthly

- Test auto-reverse

- Check sensor alignment

Every 6 Months

- Lubricate chain

- Inspect mounting hardware

Annually

- Inspect wiring

- Check door balance manually

Proper maintenance can extend unit life to 10–15 years.

Advantages and Limitations

Advantages

- Affordable installation

- Reliable chain-drive system

- Compatible with standard sectional doors

Limitations

- Louder than belt drive

- No built-in smart features

- Basic safety diagnostics

When Should You Replace Instead of Repair?

Consider upgrading if:

- Unit is over 15 years old

- Multiple components failing

- You want Wi-Fi connectivity

- Motor overheats frequently

Newer openers offer:

- Quieter DC motors

- Smartphone control

- Enhanced rolling code security

Estimated Repair vs Replacement Costs

| Option | Cost Range |

|---|---|

| Minor repair | $50–$150 |

| Chain replacement | $80–$200 |

| Full opener replacement | $400–$800 |

Repair often makes sense if motor remains functional.

FAQ: Master Mechanic 1 2 HP Garage Door Opener Manual

1. Where can I find the original manual?

Check manufacturer website archives or contact retailer support.

2. Is this opener compatible with universal remotes?

Many models are compatible with standard universal remotes using learn-button programming.

3. How long does a 1/2 HP opener last?

Typically 10–15 years with proper maintenance.

4. Can I upgrade to smart control?

Yes, by installing a third-party smart garage controller.

5. What door weight is suitable?

1/2 HP openers handle most standard residential sectional doors.

6. Why does my opener make grinding noises?

Possible worn gear assembly or loose chain tension.

Final Thoughts

Having access to a clear Master Mechanic 1 2 Hp Garage Door Opener Manual ensures safe installation, accurate programming, and reliable long-term performance. Whether you’re installing a used unit or troubleshooting an older opener, following proper setup and maintenance steps prevents costly repairs.

If this guide helped you restore or program your opener successfully, consider sharing it on social media to help other homeowners solve their garage door problems quickly and safely.

Leave a Reply