If you’re searching for ways to make your garage door operate more smoothly and quietly, nylon garage door rollers are a top choice for many homeowners. Known for their durability, quiet performance, and low maintenance needs, these rollers are an ideal replacement for older, noisier steel rollers. In this article, we’ll explore the benefits of nylon rollers, compare them to other types of garage door rollers, and provide essential tips for installation and maintenance to help you maximize your garage door’s performance.

Why Choose Nylon Garage Door Rollers?

Garage door rollers may seem like a small component, but they play a critical role in the functionality, safety, and noise level of your garage door. Nylon rollers, in particular, have become popular among homeowners and professionals alike for several reasons:

- Quieter Operation: Nylon is a softer material compared to steel, which makes it much quieter as it rolls along the track.

- Reduced Maintenance: Nylon rollers generally require less lubrication and upkeep than their metal counterparts, making them ideal for those who want a low-maintenance solution.

- Durability and Longevity: Quality nylon rollers are reinforced with ball bearings that increase their lifespan, often lasting longer than steel rollers.

- Resistance to Rust and Corrosion: Unlike steel rollers, nylon is not prone to rust, making it an excellent choice for humid or coastal environments.

Read too: Mastering Quantum Garage Door Opener Programming: A Comprehensive Guide

Comparing Nylon Garage Door Rollers to Other Roller Types

When it comes to garage door rollers, there are three main types: steel, nylon, and plastic. Here’s a breakdown of each:

1. Steel Rollers

Steel rollers are often the default type that comes with many garage doors due to their durability and low cost. While they are strong and can handle heavier doors, they can be noisy, especially as they age. Steel rollers require regular lubrication and are prone to rust over time, which can lead to rougher operation and even damage to the garage door tracks.

2. Plastic Rollers

Plastic rollers are usually the least expensive option but are not as durable as steel or nylon rollers. They’re often used on lightweight or budget garage doors. Unfortunately, plastic rollers wear out quickly and may not support the weight of heavier doors, making them less ideal for long-term use. They may also start squeaking as they age, requiring frequent replacement.

3. Nylon Rollers

Nylon garage door rollers strike a balance between the strength of steel and the quiet operation of plastic. These rollers are equipped with ball bearings to ensure a smooth and quiet glide. While they may cost more upfront, their durability, rust resistance, and noise reduction make them a preferred choice among homeowners looking for long-term performance and peace of mind.

Key Benefits of Using Nylon Garage Door Rollers

1. Enhanced Durability

High-quality nylon garage door rollers are designed to withstand the repetitive stress of opening and closing a garage door multiple times a day. Look for rollers with a higher number of ball bearings, as these tend to be more durable. For instance, 13-ball-bearing nylon rollers can support heavier doors and offer a longer lifespan.

2. Smooth and Quiet Operation

Nylon rollers are known for their quiet operation, which can be a major benefit if you have living spaces adjacent to the garage. The nylon material absorbs much of the vibration and noise typically produced by metal rollers, resulting in a smoother and quieter opening and closing process.

3. Lower Maintenance Requirements

Nylon rollers require less frequent lubrication than steel rollers. While it’s still essential to perform maintenance, especially in areas with extreme temperatures, nylon rollers tend to need less attention overall. This characteristic makes them a great option for homeowners who prefer minimal maintenance.

4. Rust and Corrosion Resistance

Since nylon rollers do not rust, they are ideal for garages located in humid or coastal areas where corrosion can be an issue. This rust resistance prolongs the life of the rollers and reduces the risk of damage to the garage door track.

5. Increased Safety

High-quality nylon rollers with enclosed ball bearings are less likely to get stuck or misalign, which enhances the safety of the garage door operation. They reduce the risk of malfunction, which could lead to potential accidents or injuries.

How to Install Nylon Garage Door Rollers

If you’re ready to upgrade to nylon garage door rollers, here are the steps to follow. Note that while it is possible to replace the rollers yourself, hiring a professional is recommended if you’re inexperienced with garage door components, especially due to the tension in the springs.

Step 1: Gather Necessary Tools

For this installation, you’ll need a set of nylon garage door rollers, pliers, a socket wrench, and safety gloves. Consider having a friend or helper for added safety.

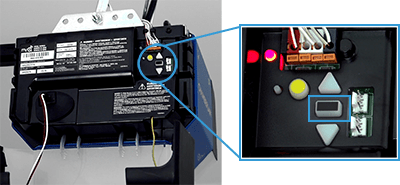

Step 2: Disconnect the Opener

Unplug the garage door opener to ensure that the door will not move unexpectedly during installation.

Step 3: Open the Door and Secure It

Lift the garage door manually to a halfway position and secure it in place. You may use clamps on the track to keep the door from moving. This position makes it easier to access the rollers.

Step 4: Remove Old Rollers

Carefully bend a portion of the track slightly open using pliers so you can slide out the old roller. Slowly pull the old roller out of the track.

Step 5: Insert New Nylon Rollers

Insert the new nylon roller into the track and secure it in the hinges. Repeat the process for each roller on both sides of the door.

Step 6: Close the Track

Once all nylon rollers are in place, use pliers to bend the track back into position.

Step 7: Test the Door

Plug the opener back in and test the door to make sure it opens and closes smoothly. Listen for any unusual sounds and check for smooth operation.

Maintenance Tips for Nylon Garage Door Rollers

To keep your nylon garage door rollers working efficiently, follow these maintenance tips:

1. Regular Inspection

Inspect the rollers every six months for signs of wear, damage, or alignment issues. Any roller that appears worn should be replaced promptly to prevent strain on other parts.

2. Lubrication

While nylon rollers require less lubrication than steel, the ball bearings still need to be greased every six months. Use a silicone-based lubricant, applying it to the roller shaft without getting any on the nylon material.

3. Check Track Alignment

Ensure that the garage door tracks are aligned and free of debris. Misaligned tracks can lead to uneven wear on the rollers and may damage the door mechanism over time.

4. Keep Tracks Clean

Use a damp cloth to clean the tracks every few months. Avoid using harsh chemicals, as they may cause buildup or corrosion, affecting the performance of the rollers.

Frequently Asked Questions About Nylon Garage Door Rollers

Q1: How long do nylon garage door rollers typically last?

Nylon rollers with ball bearings can last anywhere from 10 to 20 years, depending on the quality of the roller and how frequently the door is used. Higher-end nylon rollers with 13-ball bearings generally have longer lifespans.

Q2: Are nylon rollers compatible with all garage doors?

Yes, nylon rollers are compatible with most garage doors. However, it’s essential to select rollers that are rated for the weight and frequency of use of your specific door.

Q3: How do I know when it’s time to replace my garage door rollers?

Signs that your rollers need replacing include increased noise during operation, visible wear on the rollers, or rough movement of the door. It’s a good idea to replace all rollers simultaneously to maintain smooth operation.

Q4: Can I replace garage door rollers myself?

Yes, but garage door roller replacement can be complex, especially if you’re unfamiliar with the process. Due to the tension in garage door springs, professional assistance is recommended if you’re inexperienced.

Conclusion

Nylon garage door rollers offer an excellent combination of quiet operation, durability, and low maintenance, making them the perfect choice for homeowners who want to enhance their garage door’s performance. By investing in high-quality nylon rollers, you can enjoy a smoother, quieter garage door that requires less upkeep over time. Whether you’re upgrading from steel rollers or replacing worn-out components, nylon garage door rollers provide a long-lasting and reliable solution for any home. Regular inspection and maintenance of your nylon rollers will ensure years of optimal functionality, keeping your garage door running smoothly and quietly.

Leave a Reply